Indoor building wire and cable materials are mainly used in indoor and public places, including schools, offices, family rooms, shopping malls, supermarkets, high-speed rail stations and other places. Products include LSZH-B1 level flame retardant cable materials and B1 level oxygen barrier materials.

| Building Indoor Wire And Cable Materials | ||

| \ | LSZH Low Smoke Zero Halogen Flame Retardant Polyolefin B1 Oxygen Barrier Material | |

| \ | Irradiation Cross-linked Low Smoke Zero Halogen B1 Flame Retardant Jacket Material | |

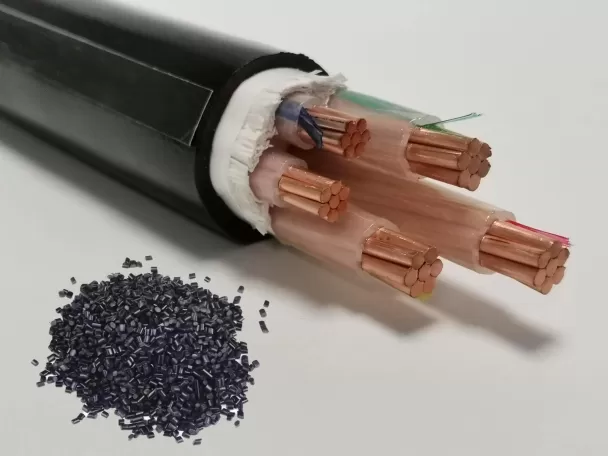

| Power Cable Material | ||

| BMS cable material | PFXBS95429 | 105°C Irradiation Cross-linked Low-Smoke Halogen-Free Flame-Retardant Insulation Material |

| PFXBK953141 | Bundled Flame-Retardant Class A Polyethylene Jacket material | |

| PFXBK953142 | Bundled Flame-Retardant Class B Polyethylene Jacket material | |

| PFXBK953143 | Bundled Flame-Retardant Class C Polyethylene Jacket material | |

| PFXGE955019 | Thermoplastic Halogen-Free Low-Smoke Flame-Retardant Insulation Material | |

| PFXBK953127 | Bundled Flame-Retardant Class C Thermoplastic Halogen-Free Low-Smoke Flame-Retardant Jacket material | |

| PFXBK953127B | Bundled Flame-Retardant Class B Thermoplastic Halogen-Free Low-Smoke Flame-Retardant Jacket material | |

| PFXBK953127A | Bundled Flame-Retardant Class A Thermoplastic Halogen-Free Low-Smoke Flame-Retardant Jacket material | |

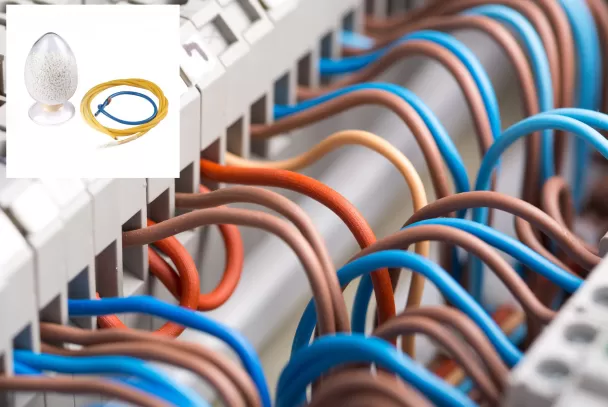

Insulated electrical wire, also known as building wire, is the most commonly used type of flexible and rigid wire in home decoration. Types like BV, BVR, RYJ, and RVS are all examples of household building wire.

Building wire has a wide range of applications, including street lighting, fire protection wiring, and wiring for various household appliances such as washing machines, water heaters, fixed sockets, central air conditioning, and microwave ovens.

While building wire can be used with many household appliances, not every specification is suitable. High-power appliances require larger gauge building wire to prevent short circuits or overheating. Common gauges include 1.5 sq mm, 2.5 sq mm, 4 sq mm, 6 sq mm, 10 sq mm, and 16 sq mm. Larger gauges like 25 sq mm, 35 sq mm, 50 sq mm, and 70 sq mm are less commonly used in home decoration.

Angreen's building wire uses silane self-crosslinking polyolefin material and is commonly used for wires of 6 sq mm and below.

| P/N | Temperature Resistance | Application &Usage |

| PFXBS95461 | 105℃ Silane XLPO HFFR Cable Copound | For extrusion of wires &cables of up to 6mm²,meet Bunch A&B |

| PFXBS95462 | 105℃ Silane XLPO HFFR Cable Copound | For extrusion of tubes &pipes of up to 6 mm²,meet Bunch A&B |

| PFXBS95463 | 105℃ Silane XLPO HFFR Cable Copound | For extrusion of wires &cables of up to 6mm²,meet Bunch A&B&C |

| PFXBS95464 | 125℃ Silane XLPO HFFR Cable Copound | For extrusion of wires &cables of up to 6mm²,meet Bunch A&B |

| PFXBS95465 | 125℃ Silane XLPO HFFR Cable Copound | For extrusion of tubes &pipes of up to 6mm²,meet Bunch A&B |

| PFXBS95466 | 125℃ Silane XLPO HFFR Cable Copound | For extrusion of wires &cables of up to 6mm²,meet Bunch A&B&C |

The selection of building indoor wire and cable materials needs to consider many factors, including safety, durability, fire resistance, environmental protection and cost-effectiveness.

The Following are some commonly used building indoor wire and cable materials and their performance characteristics:

Heat resistance: XLPE cable has high heat resistance and is suitable for high-power circuits.

Mechanical strength: XLPE cable has excellent mechanical strength and wear resistance.

Environmental stress resistance: XLPE material has good resistance to environmental stress cracking.

Rubber (Such as Ethylene Propylene Rubber EPR)

Heat resistance: Rubber cable has good heat resistance and is suitable for high temperature environment.

Flexibility: Rubber cable is soft and easy to install and wire.

Flame Retardant Low Smoke Zero Halogen Material (LSZH)

Flame retardancy: In the event of a fire, LSZH cables produce less smoke and toxic gases.

Environmental protection: It does not contain halogens and does not produce harmful gases when burned.

Shielding Material

Anti-interference: Shielded cable can reduce electromagnetic interference and ensure the stability of signal transmission.

When selecting indoor wire and cable materials, you also need to consider the cable's rated voltage, current capacity, laying method (such as pipeline laying, open laying, concealed laying, etc.), ambient temperature, and whether special properties are required (such as wear resistance, corrosion resistance, etc.).