The high-voltage cable materials for new energy vehicles in our company are mainly cross-linked polyolefin materials, which are divided into XLPE and XLPO.

According to the flame retardant and temperature resistance levels, they are divided into 125℃ XLPE\XLPO automotive high-voltage wire materials and 150℃ XLPE\XLPO automotive high-voltage wire materials.

| New Energy Vehicle Cable Materials | ||

| Hige Voltage Cable Material Inside New Energy Vehicles | PFXOR85510 | 125°C irradiation cross-linked low-smoke zero halogen flame-retardant cable material for large wires of new energy vehicles |

| PFXOR95529 | 125°C irradiation cross-linked low-smoke zero halogen flame-retardant cable material for small wires of new energy vehicles | |

| PFXOR85616 | 150°C irradiation cross-linked low-smoke zero halogenflame-retardant cable material for large wires of new energy vehicles | |

| PFXOR96629 | 150°C irradiation cross-linked low-smoke zero halogen flame-retardant cable material for small wires of new energy vehicles | |

| Automotive Thin Wall Wire Mateial | PFXBS97539 | 125°C irradiation cross-linked low-smoke zero halogen flame-retardant cable material for thin-walled automotive wire |

| PFXBS97539H | 125°C irradiation cross-linked low-smoke zero halogen flame-retardant cable material for thin-walled automotive wire | |

| PFXBS97639 | 150°C irradiation cross-linked low-smoke zero halogen flame-retardant cable material for thin-walled automotive wire | |

| PFXBS97639H | 150°C irradiation cross-linked low-smoke zero halogen flame-retardant cable material for thin-walled automotive wire | |

Automotive wiring harnesses are essentially designed for the long-term reliable transmission of power and signals in extreme environments. Therefore, their manufacturing materials must meet the following criteria: Temperature resistance (85°C–200°C), resistance to oil, coolant, and salt spray, flame retardancy, low smoke, and low toxicity, resistance to mechanical stress (vibration, friction, compression), and long lifespan (automotive-grade requirement ≥15 years).

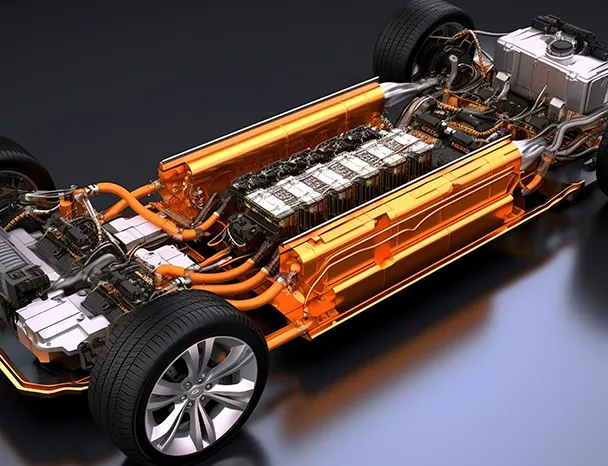

Automotive High-Voltage Wiring Harness Materials (300–1000V): Used in new energy vehicle electric drive systems. Materials must meet standards such as ISO 19642 and LV216-2.

Insulation materials: XLPE cable material is the mainstream material in the industry, with a temperature resistance of 125°C–150°C, high dielectric strength, and aging resistance, making it the preferred insulation material for high-voltage power lines. XLPO, similar to XLPE, is also commonly used in the production of automotive high-voltage cables.

It has a temperature resistance range of 180℃–200℃, is extremely flexible, has excellent cold resistance (not brittle at -60°C), and stable insulation performance. It's used in the extreme temperature areas of electric drive compartments, high-voltage connector tail cables, and high-temperature, high-voltage cables near motors/exhaust systems and other high-heat areas.

Applications: Headlights, interior trim, sensors, electronic control units, body control, etc.

Standards: ISO6722, LV112, JASOD611.

XLPE (cross-linked polyethylene) material is the main material for thin-walled cable production. It has a temperature resistance of 125°C, significantly reduced thickness, and improved mechanical strength. The sheath layer (used to wrap multiple thin-walled wires) often uses XLPO cross-linked polyolefin.

ABS sensor wires belong to signal wires + special mechanical condition cables, with relatively high requirements, therefore the material system is unique.

XLPE/XLPO is commonly used, with a temperature resistance of 105–125°C, high stability, and resistance to hydrolysis. TPU material is also a mainstream application material for ABS automotive brake sensor cables, offering excellent properties such as high abrasion resistance, scratch resistance, mechanical shock resistance, and low-temperature bending resistance.

High-Frequency Signal Cables Must Meet EMC, impedance control, and temperature and oil resistance requirements.

Angreen Company commonly uses TPE (TPE-E/TPE-U), which offers good flexibility, oil resistance, and scratch resistance.

The selection of high-voltage cable materials in new energy vehicles is crucial because they directly affect the performance and safety of the vehicle. High-voltage cables in vehicles need to have properties such as high and low temperature resistance, oil and water resistance, flame retardancy, tear resistance, insulation, and UV aging resistance.

XLPE material has become a common insulating material for high-voltage cables due to its heat resistance and mechanical properties. At the same time, the design of high-voltage cables in vehicles also needs to consider factors such as wiring space, high current and high voltage, high and low temperature environment, and harsh conditions of the vehicle driving environment.

The selection and design of high-voltage cables in new energy vehicles must meet relevant international and domestic standards, such as ISO 6722, QC/T 1073, CQC1122, etc., to ensure the performance and safety of the cables. The insulation layer material of the cable needs to have good heat resistance and mechanical strength to adapt to the high temperature and mechanical pressure inside the vehicle. In addition, the high-voltage cable should also have high flexibility to adapt to the tight bending radius and continuous vibration environment inside the vehicle.