This product is made of high-purity resin as the base material, and is mixed with flame retardants, reinforcing agents, antioxidants, etc. for extrusion and granulation. CPE wire sheath materials and insulation materials have excellent properties such as heat resistance and weather resistance, no precipitation pollution, meet the relevant requirements of Rohs, etc., and are easy to extrude and process. It meets the requirements of GB/T5013.4&6, VDE0282-4&6, IEC 50363-2-1, JIS C3301, UL62 and other standards.

Product Features

· Hardness 60-90A, good flexibility, high flame retardancy, good oil resistance;

· CPE cable materials are divided into electron irradiation type and vulcanization type, with low extrusion temperature, fast extrusion and vulcanization;

· Excellent electrical insulation performance, slightly lower than EPDM;

· Good weather resistance, good flexibility at low temperature of -35℃, common temperature resistance grades of 60℃, 90℃, and 105℃.

Application Areas

· Power cord sheath materials that meet the SE3, SE4, EM2, and EM3 requirements of GB5013, EN50525-2-21, EN50363-2-1, and VDE0282-4 below 1kV, and power cord insulation materials that meet the IE4, EI4, and EI6 requirements of GB5013, EN50525-2-21, EN50363-1, and VDE0282-4.

· CPE wire insulation and sheath materials that meet the requirements of JIS C3301 below 1kV,and CPE wire insulation and sheath materials that meet the requirements of UL62 for 600V and below.

Chlorinated polyethylene(CPE)is a polymer material made from high-density polyethylene(HDPE)through chlorination reaction. It has good heat aging resistance, ozone and weathering resistance, oil and solvent resistance, electrical properties and flame retardancy. These characteristics of CPE make it an important rubber material in the wire and cable industry.

In the wire and cable industry, CPE is mainly used to manufacture cable sheath materials. Due to its heat resistance, the maximum operating temperature of CPE cable can reach 75-85℃, or even higher. CPE vulcanizate has excellent ozone and weathering resistance, can maintain stable performance under harsh conditions, and is not prone to cracking. In addition, CPE's oil resistance and chemical resistance make it show good stability in various oil and chemical environments.

Although the electrical properties of CPE limit its application in high-voltage insulation materials,its heat resistance, aging resistance and wear resistance make it an ideal material for cable sheaths. CPE's flame retardant properties are also very outstanding. It does not spread fire and can form an ash layer to prevent the spread of flames under the action of flames, thereby improving the safety of wires and cables.

In terms of processing technology, CPE can be cross-linked by high-temperature thermal cross-linking or electron irradiation, providing a variety of processing options. CPE has good processing performance, is easy to mix with other rubbers and plastics, and has good durability, which makes CPE widely used in the wire and cable industry.

| Testing items | VALUE | Typicalvalue | UNIT | Test Method | |

| Cable sheath material | |||||

| Specific Gravity | 1.52±0.03 | 1.52 | g/cm3 | GB/T1033 | |

| Hardness | 72±3 | 72 | Shore A | GB/T-531/ISO7619 | |

| Tensile Strength | ≥ 7 | 8.2 | MPa | GB-T2951.11 | |

| Elongation at Break | ≥ 500 | 710 | % | GB-T2951.11 | |

| Cable Insulation material | |||||

| Specific Gravity | 1.61±0.03 | 1.61 | g/cm3 | GB/T1033 | |

| Hardness | 80±3 | 80 | Shore A | GB/T-531/ISO7619 | |

| Tensile Strength | ≥ 3 | 4.1 | MPa | GB-T2951.11 | |

| Elongation at Break | ≥ 450 | 680 | % | GB-T2951.11 | |

| Environmental Requirement | |||||

| Meet ROHS、REACH。 | |||||

| Material | CPE Chlorinated Polyethylene | ||||

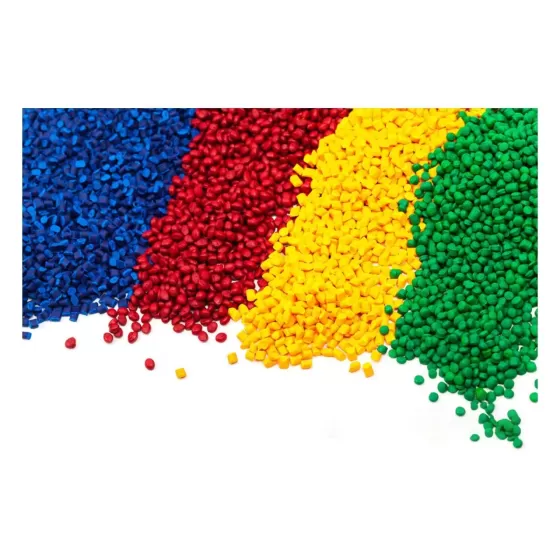

| Color | Sheath:Black、White、Grey Insulation:Black、White、Yellow、Brown、Blue、Green、Purple | ||||

| Shape | Granular | ||||

| Remark | / | ||||