·Lightweight and low density (below 0.4-0.8g/cm³), similar to the density of the material used in 3D printing filament production, making it suitable for applications requiring reduced weight and density.

·Cracking resistance and high tensile strength, which ensures printed parts made with the material remain durable.

·Acid and alkali resistance, corrosion resistance.

·Excellent oil resistance.

·Excellent elasticity and soft appearance, comparable to flexible filament commonly used in 3D printers.

·Good hydrolysis resistance, ensuring long-term performance even in humid environments.

·Good wear resistance and heat resistance, tolerating higher temperatures during manufacturing or use.

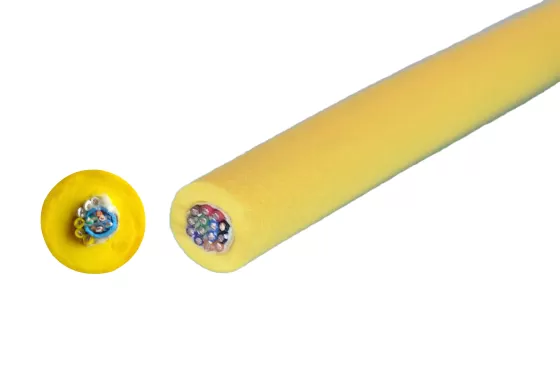

The surface of the foamed cable is dense, the internal pores are uniform, and the foaming rate is high, achieved using advanced foaming technology.

Commonly used in the manufacture of new energy charging pile wires and cables, plug materials, wire outer sheaths, medical cables, and marine floating cables.

Foaming TPU is a cable material that uses thermoplastic polyurethane (TPU) as a base material and is foamed by adding a foaming agent. This material is increasingly used in the wire and cable industry due to its unique properties.

Light Weight: The density of foamed TPU can be controlled at 0.70-0.80 g/cm³, enabling cables to float on the water surface, a property also valued in 3D printing filaments designed for lightweight objects.

High Flexibility: Foaming TPU cable materials maintain the flexibility of TPU, akin to the benefits of using flexible filament in 3D printers, ensuring ease of installation and deployment.

Good Wear Resistance and Tensile Strength: Foamed TPU inherits the wear resistance and high tensile strength of TPU, making it suitable for harsh environments, whether in traditional applications or for 3D-printed parts.

Thermal Insulation Performance: The pore structure of foamed TPU provides good thermal insulation, allowing its use in cables requiring heat preservation or higher temperatures.

Environmental Protection: TPU material is recyclable. Like advanced 3D printing filaments, foamed TPU meets environmental protection standards, making it ideal for eco-conscious industries.

Raw material preparation: TPU and compatibilizer are dried to remove moisture, ensuring optimal performance, especially for applications involving 3D printers and foaming technology.

Mixing: Add TPU, foaming agent, antioxidant, PP (polypropylene), compatibilizer, and anti-hydrolysis agent into the mixer in a certain proportion and mix at high speed, mimicking processes used to prepare varioshore TPU for 3D printing filament.

Extrusion granulation: Extrusion granulation of the mixed raw materials through an extruder to form a foaming TPU composition, comparable to manufacturing techniques for FDM/FFF 3D applications.

| Properties | Standard Value | Typical Value | Unit | Test Method |

| Physical properties | ||||

| Density | 0.4-0.8 | 0.5-0.8 | g/cm³ | GB/T 1033 |

| Hardness (6mm plate) | 85±3 | 85 | HA | GB/T 2411 |

| Brittle temperature | ≤-60 | -60 | ℃ | GB/T 5470 |

| UL temperature grade | 90 | 90 | ℃ | UL |

| Mechanical properties | ||||

| Tensile strength before aging | ≥20 | 25 | MPa | GB/T 1040 |

| Elongation at break before aging | ≥400 | 603 | % | GB/T 1040 |

| Tensile strength retention rate | ≥70 | 76 | % | GB/T 2951.12 |

| Elongation at break retention rate | ≥70 | 91 | % | GB/T 2951.12 |

| Tear resistance | ≥40 | 50 | N/mm | CQC1103-2015 B |

| 80℃*168H Hot water resistance | ||||

| Tensile strength retention rate | ≥70 | 80 | % | |

| Elongation retention rate | ≥70 | 85 | % | |

| Electrical properties | ||||

| Volume resistivity at 20℃ | ≥1.0×10^10 Ω·cm | 1×10^11 Ω·cm | Ω·cm | IEC 60093 |