Low-density polyethylene (LDPE) is a flexible thermoplastic material made by polymerizing ethylene under high pressure. Due to its more branched molecular chains and looser structure, it has a lower density, usually between 0.91 and 0.94 g/cm³. LDPE is widely used in packaging, construction and consumer products due to its flexibility, chemical resistance and ease of Processing.

LDPE's unique properties stem from its molecular structure, which gives the material its soft physical properties and excellent chemical stability. The following are the main performance characteristics of LDPE:

1. Softness and Flexibility

LDPE has high flexibility, even at low temperatures can maintain good flexibility, suitable for the manufacture of flexible films and foldable products.

2.Chemical Resistance

LDPE has good resistance to most acids, alkalis, salt solutions as well as alcohols and esters, so it can be used for chemical packaging.

3. Good Electrical Properties

With low dielectric constant and excellent electrical insulation properties, it is ideal for wire and cable insulation materials.

4. Low Density and Light Weight

LDPE has a low specific gravity and is lightweight but has a certain mechanical strength, making it suitable for lightweight applications in a variety of scenarios.

5. Excellent Processing Performance

LDPE has good melt fluidity and can be molded by blow molding, extrusion, injection molding and other processes.

LDPE is an easy-to-process material that is widely applicable to a variety of production processes:

Blow molding: mainly used for manufacturing films, such as food packaging film, agricultural film and garbage bags.

Extrusion molding: to produce products such as pipes, cable coverings and plastic sheets.

Injection molding: Suitable for making thicker products such as containers, toys, and daily necessities.

Rotational molding (rotational molding): for making hollow products such as water storage tanks and chemical containers.

When processed, LDPE is usually molded at temperatures ranging from 170~230°C and is highly adaptable to meet the production needs of complex shapes and products of different thicknesses.

1. Packaging Materials

LDPE has a pivotal position in the packaging industry, its flexibility and transparency make it the first choice for many packaging materials:

Food packaging: LDPE films are widely used to make cling film, frozen food bags and heat-sealable bags, ensuring fresh and odorless food.

Industrial packaging: such as shrink and protective films, used to wrap mechanical equipment and construction materials to prevent damage during transportation.

Agricultural film: LDPE agricultural film is widely used for greenhouse coverings and mulch to provide a suitable growing environment for crops.

2. Construction and Engineering

In the construction field, LDPE's moisture-proof, chemical-resistant and flexible properties open up a wide range of applications:

Waterproof material: LDPE film can be used as building moisture-proof layer or waterproof layer, widely used in basement, tunnel and subway projects.

Pipe and pipe lining: LDPE pipe is lightweight, corrosion-resistant and suitable for low-pressure water supply systems and chemical liquid transportation.

Cable cladding: In wire and cable, LDPE is used as an insulating material or outer sheath with excellent abrasion resistance and insulating properties.

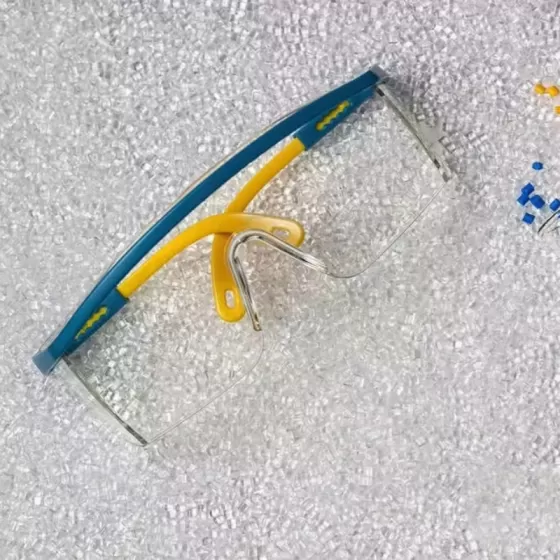

3. Consumer & Household Goods

Due to its safety and flexibility, LDPE is also widely used in daily consumer products:

Daily necessities: LDPE is used in the manufacture of plastic bags, garbage bags, cleaning bags, etc. It is one of the most common plastic materials in daily life.

Children's toys: Its non-toxicity and flexibility make LDPE ideal for producing soft toys and protective pads.

Storage containers: such as flexible water tanks and storage bags, LDPE is lightweight and easy to fold for home use.

4. Medical and Hygiene Industry

LDPE's chemical stability and non-toxic properties make it also important for use in the medical and healthcare field:

Disposable medical products: such as syringe bags, infusion bags, to ensure material safety and durability.

Packaging for hygiene products: e.g. outer packaging for diapers and sanitary napkins, soft and waterproof.

5. Agriculture and Fisheries

In agriculture and fisheries, LDPE is used as a lightweight and durable material:

Fishing nets and floats: LDPE has good water resistance and lightweight characteristics, and is widely used in fishing equipment.

Water storage and irrigation systems: Flexible LDPE pipes can be used for farm irrigation with the advantages of weather resistance and easy installation.