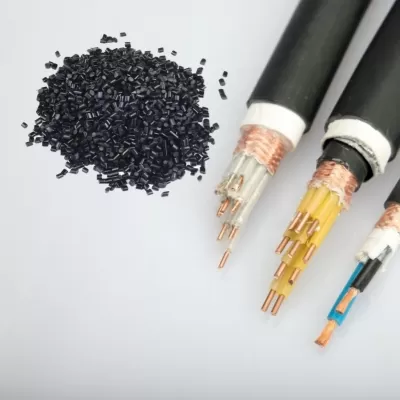

Low-smoke, halogen-free polyolefins are widely used in the cable industry. This material is ideal for modern cable jacketing and insulation due to its low toxicity, low smoke properties and excellent flame retardancy.

Low Smoke and Halogen Free Polyolefin (LSZH PO) is a polymer material made by modifying a polyolefin, such as polyethylene or polypropylene, by removing halogen elements and adding flame retardant fillers.

1. Low Smoke Emission

During combustion, LSZH PO releases much lower smoke concentrations than traditional halogenated materials, and the higher transparency of the smoke greatly improves visibility in case of fire.

2. No Halogen Toxicity

No halogen-containing acidic gases will be produced during combustion, avoiding secondary damage to human health and equipment.

3. Excellent Flame Retardancy

With the addition of special flame retardant, the low smoke halogen free polyolefin material can meet the stringent flame retardant requirements, such as UL94 V-0 grade, suitable for high requirements of cable products.

4. Good Mechanical Properties

With high tensile strength and abrasion resistance, it can maintain the integrity of cables in harsh construction environments.

5. Easy Processing

The material can be molded by extrusion, injection molding and other processes in the production process, suitable for various specifications of cable manufacturing.

With excellent performance, low-smoke halogen-free polyolefin has a wide range of applications in many industries, especially in the field of environmental protection and safety requirements:

1. Building Cables

In high-rise buildings, residential and commercial centers, low-smoke halogen-free polyolefin is widely used in cable jacketing and insulation to reduce the concentration of smoke and toxic gas emissions in the event of a fire.

2.Rail Transportation Locomotive Cables

A large number of cables used in subway, high-speed rail and light rail systems need to meet strict flame retardant and low-smoke standards, and low-smoke halogen-free polyolefin has become the material of choice.

3. Data Centers, Communication Networks

These places require a large number of cable wiring, low-smoke halogen-free polyolefin materials not only to ensure the safety of wiring, but also reduce the risk of equipment damage caused by fire.

4. Energy And Photovoltaic Industry

Low-smoke halogen-free polyolefin materials in new energy cables and photovoltaic cables in a wide range of applications, its high temperature resistance, aging resistance characteristics for the development of the industry to provide support.

Compared with traditional cable materials, low-smoke halogen-free polyolefin has obvious technical advantages, specifically in the following areas:

1. Environmental Performance

Halogen-free components to ensure that the green properties of the material, combustion produces only a small amount of water and carbon dioxide, friendly to the environment.

2. Weather Resistance And Anti-aging Ability

The material has good UV resistance and chemical resistance, and can still maintain stable performance when used outdoors for a long time.

3.High Temperature Performance

The continuous working temperature of the low-smoke halogen-free polyolefin material can reach 90℃ or higher, which meets the temperature requirements of most industrial and architectural applications.

4. Recyclability

Low-smoke, halogen-free polyolefin materials are easy to recycle, in line with increasingly stringent global sustainability regulations.